Sewer Information

Navigate this page via search or the table of contents.

The Collection System

Any matter that enters a sewer drain passes through pipes via gravity to the wastewater treatment plant. It may make a pit stop at one or more pumping stations, where it passes through a grinder for refinement and then pumped past a low spot back into the system.

North Londonderry Township maintains six (6) pumping stations, over 700 manholes and over 36 miles of sewer pipes. These assets and their components are maintained and inspected annually to ensure proper operation. The Township is responsible for the sewer main line. While homeowners are responsible for the lateral to the main and the connection to the main.

Pollutants Cause Problems

The sanitary sewer collection system gathers used and dirty water from sinks, toilets, washing machines and bathtubs. Therefore, it is imperative for homeowners to monitor what goes down these drains. It may be surprising to know the following items cannot only clog and backup the system, but are extremely costly to the treatment process.

Water Pollution

Rain And Groundwater

The Lebanon County Stormwater Ordinance restricts stormwater from entering into the public sewer collection system. The influx of water in the collection system can cause overflows or backups into someone’s house, streets or waterways.

Rainwater Through A Broken Or Missing Vent Cap

Every gallon of rainwater entering the treatment plant negatively effects the process and leads to increased user costs. Help us prevent this by checking the lid on your outside cleanout pipe – white mushroom-looking vent cap, or screw-on lid. As long as the waterproof lid is in good condition, securely fastened, and six (6) inches above the ground, it can prevent rainwater from seeping into the sewer system. Replace any cracked or broken lids.

Pool Water

Much like some of the other pollutants in this list, the influx of water flow can increase the cost of treatment which is then passed on to the customer. The unexpected chemicals may seep through the treatment process and into local waterways posing a health risk.

Other Pollution

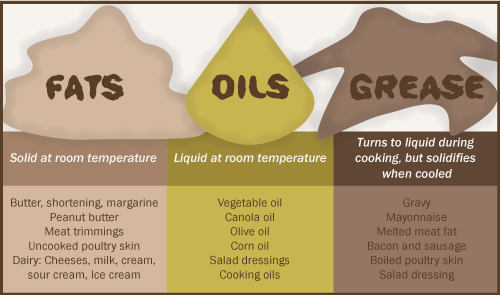

Fats, Oils And Greases

The most common culprit of a sewer clog is the build-up of hardened fats, oils, and grease (FOG). These are by-products of cooking that come from meat fat, lard, oil, shortening, butter, margarine, food scraps, baked goods, sauces and dairy products. Eventually, FOG harden and attach to solids normally found in a sewer pipe forming clumps. These clumps stick to the sides of pipes, slowing down the flow. This build-up grows and clogs the pipes, ultimately causing a sewer backup in your house or yard.

The best way to prevent this type of backup is to prohibit fats, oils, and greases from entering the drain. When cooking, soak up FOG with a paper towel or place in a sealable container and throw it in the trash. This is a great way to reuse take-out containers! Despite their claims, hot water and detergents do not dissolve grease. They only pass it down the line to cause problems elsewhere.

Household Chemicals Or Medications

Unused chemicals or medications should never enter the sewer system. The treatment process is not designed to process these pollutants.

Visit our Recycling Page for proper disposal of Household Hazardous Waste and pharmaceuticals.

Disposal Wipes

Sewer systems carry used water from sinks, toilets, showers and laundries away from a home. Flushing ‘unflushable’ items that do not break down in water (e.g. garbage, paper towels, disposable wipes, kitty litter, cigarette butts) causes blockages in pipes leading to costly backups and treatment. “Disposable” does not mean flushable. Disposable means the product is intended for single use. Most baby and adult wipes are not flushable because they do not disintegrate in water like toilet paper does.

New Home Building Specifications

If you plan to build a new home and the property is within 150 feet of a sanitary sewer main, sewage disposal must be connected to the collection system. The builder or plumber doing the work can obtain a permit for connection at the Township Office. Please call before arriving to allow staff time to prepare the permit in advance.

On-Lot Sewage

Properties with private well and on-lot sewage disposal systems make up most of the northern half of North Londonderry Township. Besides the North Hills development, this would consist of all properties north of State Route 422 / Main Street, Palmyra. A permit is required for any new install, repair, replacement or modification to a system. Contact the Lebanon County Planning Department at (717) 228-4444 for a permit.

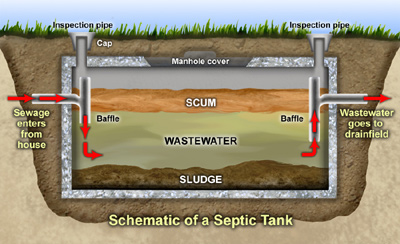

Sewage Management Program

As a result of DEP requirements and guidelines established by the Act 537 program, the Township instituted a Sewage Management Program in 2010 that initiated routine inspection and maintenance requirements for properties that have a septic system to ensure proper operation. Therefore, property owners with on-lot sewage systems are required to submit proof of pumping every three (3) years. To do so, submit the Sewage Management Report along with the administrative fee to the Township Office. The homeowner should sign and complete Section I of the report. The pumper/hauler will sign and complete Section II. If you misplaced or did not receive the form, please contact us prior to scheduling pumping.

Resources…

Wastewater Treatment Plant

Since 1976, when the Township established public sewer service in town, we have been working together with the Borough of Palmyra to treat wastewater from residents’ homes. After a half-century of service at the Borough of Palmyra Wastewater Treatment Plant (WWTP), North Londonderry Township swapped responsibilities with the Borough. In April 2011, construction began on a $15 million project to improve treatment and expand capacity.

The new plant was built on about 17 acres of former Millard farm land in South Annville Township. At this time, North Londonderry Township Wastewater Treatment Plant is treating 900,000 gallons of wastewater a day from residential, commercial and industrial sources. At capacity, it will handle up to 1.5 million gallons/day (MGD), which leaves room for wastewater from an additional 1,500 homes. The Borough of Palmyra pays their share of fees, based upon usage, which can amount to 43% of total plant flow. Due to its location within the community, special attention was given to keep the plant out of sight. Laid out around an existing fieldstone barn and 20 large 80-year-old sycamore trees, the treatment works are set up on a hill behind a new garage and administration building for partial concealment. This design also limits the amount of storm run-off that enters the treatment process.

Innovative construction features include passive solar lighting, the use of effluent (treated water leaving the plant) to heat and cool buildings, insulated concrete block and metal roofing that will last longer than traditional asphalt shingles. The new garage utilizes an infrared heating system and automated equipment minimizes staffing requirements. The self-regulating equipment monitors its own operating conditions and notifies staff if a parameter goes out of range as well as only running what equipment is necessary thus, saving energy.

How Does A Treatment Plant Work?

Filters remove plastic, grease and paper from sewage transported via the collection system to the plant. Sewage then flows into two 1.3 million gallon tanks, where natural bacteria digest and decompose any biosolids with the assistance of aeration – by way of a revolving arm – and water. Two smaller clarifier tanks then separate the liquids from the solids. From there, the liquid is sent to a filter building to disinfected with ultraviolet light and chlorine. On average, 900,000 gallons of effluent is returned to Killinger Creek every day. But wait, what happened to the solids? They are dried and reduced down to 20% matter that is transported to the county landfill.

The new plant operates with four employees, all certified DEP Wastewater Operators. The North Londonderry Township Highway Department performs maintenance on the collection system. We have our own full-time DEP accredited lab that tests the successes of plant processes in treating sewage before its ultimate elimination into the surrounding environment. Annual operating cost is budgeted at $1.4 million.